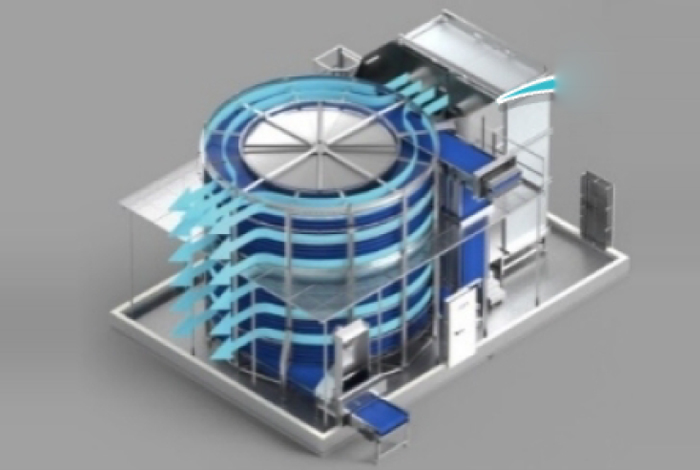

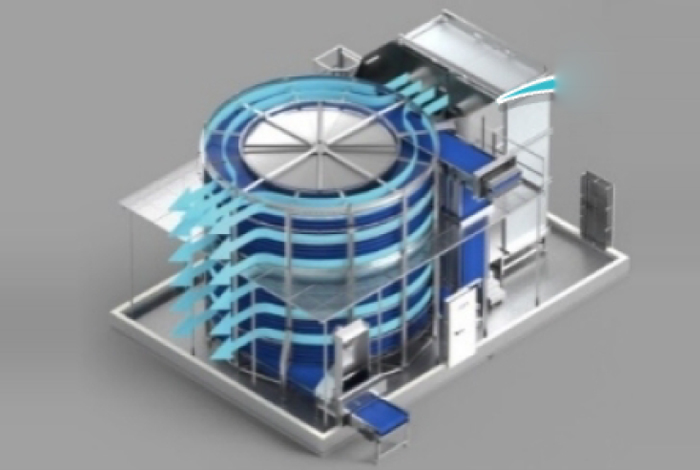

Spiral freezer

Zhongtong Food Machinery has been focusing on the manufacturing of various food machinery for 20 years, designing a complete set of assembly line process equipment from raw material pretreatment to final product packaging and storage for nearly a thousand domestic and foreign customers, providing users with complete solutions. In the past 20 years of development and progress, we have not only established a good brand image among domestic large and medium-sized customer groups, but also exported some of our equipment to multiple countries and regions such as Europe, Australia, Africa, Japan and South Korea, and Southeast Asia, receiving widespread praise and recognition from many users. We are rigorous, diligent, and strive for excellence. We humbly listen to feedback from every customer, continuously improve and perfect, and strive for customer satisfaction while also continuously improving the performance of our products. Our design team is also gaining increasingly rich design experience through long-term integration with users. Able to fully understand and grasp customer intentions and requirements.

Structure and characteristics

-

The top mounted drive system synchronized with Europe features lower energy consumption, a safe and hygienic internal environment, and a more user-friendly maintenance space;

-

Horizontal air supply: The evenly distributed cold air blows horizontally towards the surface of the food, greatly shortening the outlet and return air paths of the evaporator, minimizing the temperature difference between the outlet and return air, and reducing the drying loss of frozen products. The evaporator and the outer side of the rotating cage are connected by stainless steel guide plates, forming a reasonable and smooth guide air duct together with the insulation storage body, ensuring that the wind force is uniform at different positions of the mesh belt, allowing the frozen products to achieve the best heat exchange effect, and effectively reducing the frosting speed of the evaporator;

-

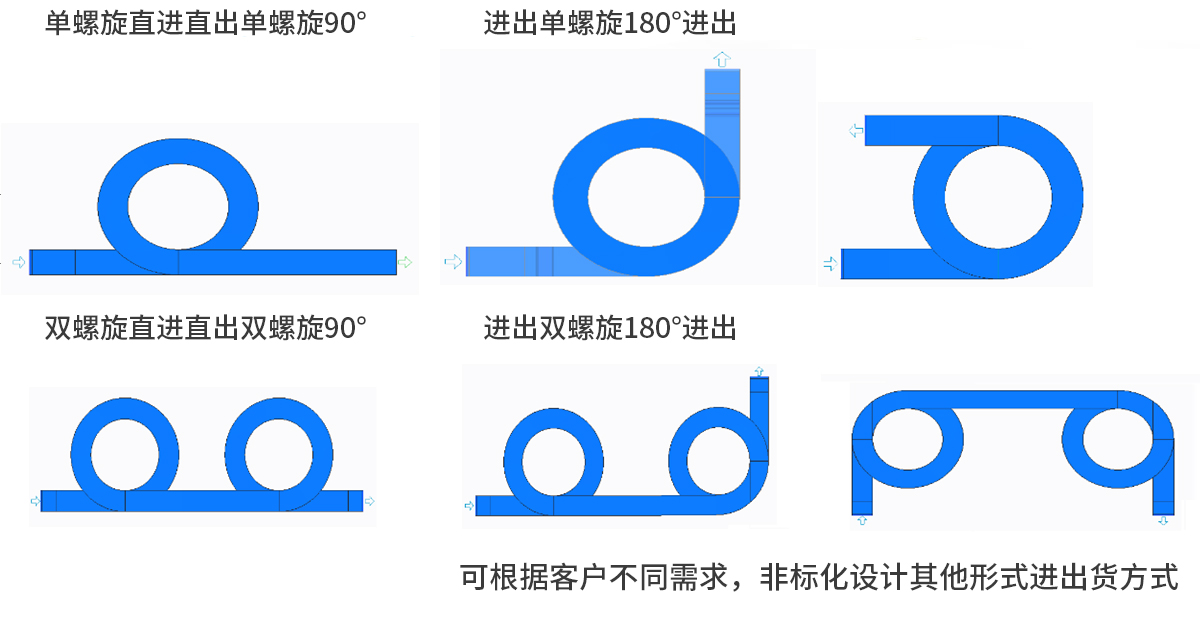

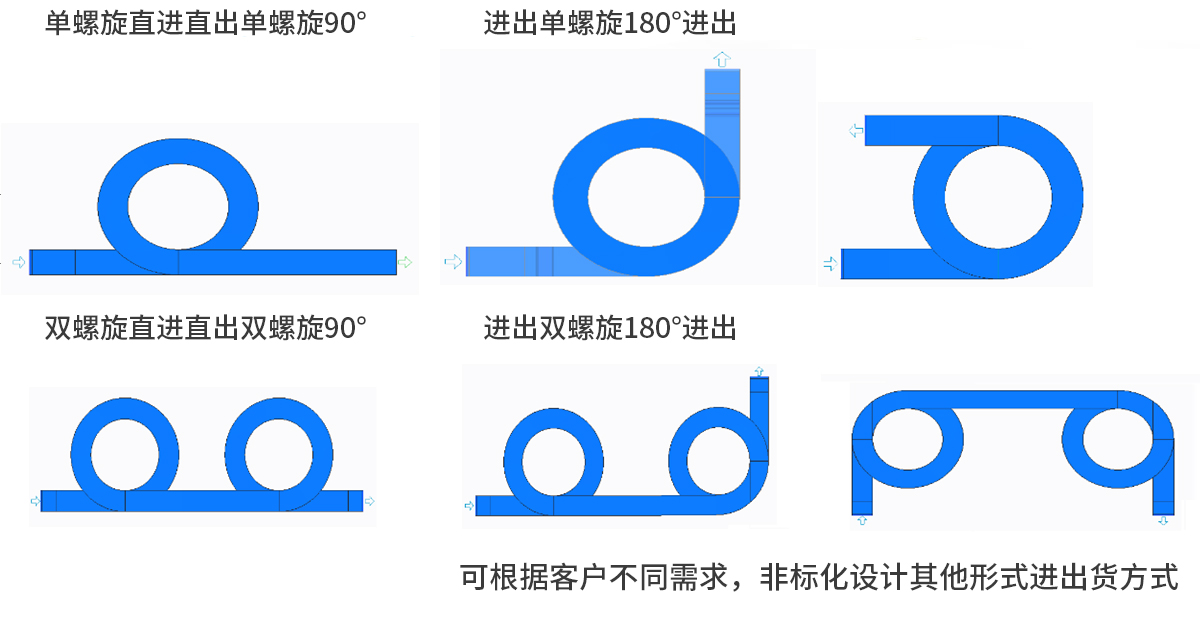

Multiple combinations and import and export methods: single spiral import and export method, low level feeding, high level discharging or high level feeding, double spiral low level feeding, low level discharging, two or more spiral combinations to form multi temperature zone quick freezing machines, especially suitable for cooling or quick freezing production lines in central kitchens and other fields;

-

The multi-point abnormal alarm monitoring system monitors the working status of the spiral quick freezing machine in real time, can immediately alarm and display the fault point and cause, and protect all transmission components from damage. Multi point mesh belt anti overturning devices are installed in the conveyor belt area to ensure stable operation of equipment, upper and lower limit warning is set for floating counterweight devices to ensure smooth operation of the conveyor belt in case of temperature changes, and emergency stop devices are set at the inlet and outlet to stop the machine at any time in case of emergency.

Customizable design for import and export methods

中文

中文

中文

中文