Self stacking spiral freezer

Zhongtong Food Machinery has been focusing on the manufacturing of various food machinery for 20 years, designing a complete set of assembly line process equipment from raw material pretreatment to final product packaging and storage for nearly a thousand domestic and foreign customers, providing users with complete solutions. In the past 20 years of development and progress, we have not only established a good brand image among domestic large and medium-sized customer groups, but also exported some of our equipment to multiple countries and regions such as Europe, Australia, Africa, Japan and South Korea, and Southeast Asia, receiving widespread praise and recognition from many users. We are rigorous, diligent, and strive for excellence. We humbly listen to feedback from every customer, continuously improve and perfect, and strive for customer satisfaction while also continuously improving the performance of our products. Our design team is also gaining increasingly rich design experience through long-term integration with users. Able to fully understand and grasp customer intentions and requirements.

Self stacking spiral freezer

-

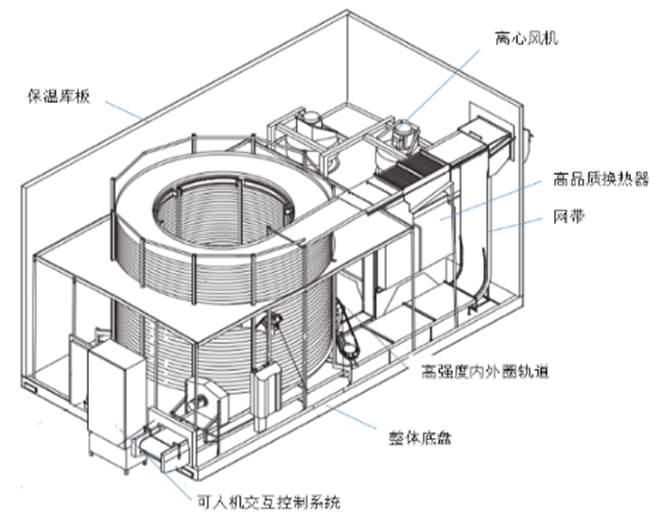

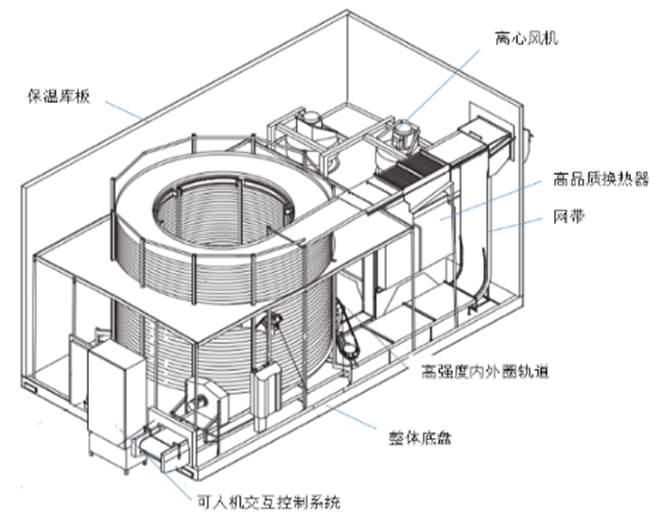

The self stacking spiral freezer mainly consists of modular insulation bottom plate, insulation storage plate, high-strength inner and outer ring track, mesh belt, transmission mechanism, heat exchanger, centrifugal fan, inlet and outlet, control system, etc. It can be equipped with ADF defrosting system and CIP cleaning system.

Structure and characteristics

-

The outer side of the mesh belt is directly driven by gears, and the mesh belt is connected to the sliding rail friction bar through a slider for friction operation. The friction coefficient between the polymer and the polymer material is relatively small compared to stainless steel, and the material itself has lubrication, which is not easy to produce dirt and has low friction force. Structurally, compared to conventional spiral freezers, it eliminates the need for an intermediate rotating cage and eliminates the wear of components caused by static friction transmission between the rotating cage and the mesh belt; In addition, the special structure of the sliding block on the mesh belt is coupled to ensure that the belt will never be flipped, completely solving the problem of downtime and maintenance caused by flipping the belt.

-

Vertical air supply, the stacked spiral quick freezing device adopts vertical air supply, and all cold air passes through multi-layer mesh belts from top to bottom; At the same time, the mesh belt baffle is equipped with a certain number of ventilation holes, which can form radial airflow on the surface of the mesh belt; Food is always frozen under the combined action of vertical and horizontal cold air, resulting in high product freezing efficiency;

-

Excellent energy-saving feature: The mesh belt has a small driving force, so only a smaller power motor is needed. Adopting centrifugal fans, with high air pressure and volume, requires fewer fans;

-

Unique conveyor system: sealing the frozen area of the product, improving the utilization rate of cold energy, and preventing the product from being blown off; Mesh belt tensioning device, automatically adjusting tension to prevent tape jamming and flipping.

中文

中文

中文

中文